振动电机vibrating motor

使用说明书operation instruction

欢迎使用我公司生产的JZO、YZO、YZD(YZS、YZU)、TZD(TZDC)YZDP系列卧式振动电机、T05系列立式振动电机

Welcome to use JZO、YZO、YZD(YZS、YZU)、TZD(TZDC)YZDP horizontal vibrating motor,T05 vertical vibrating motor.

一、用途与特点

1.use and characteristic

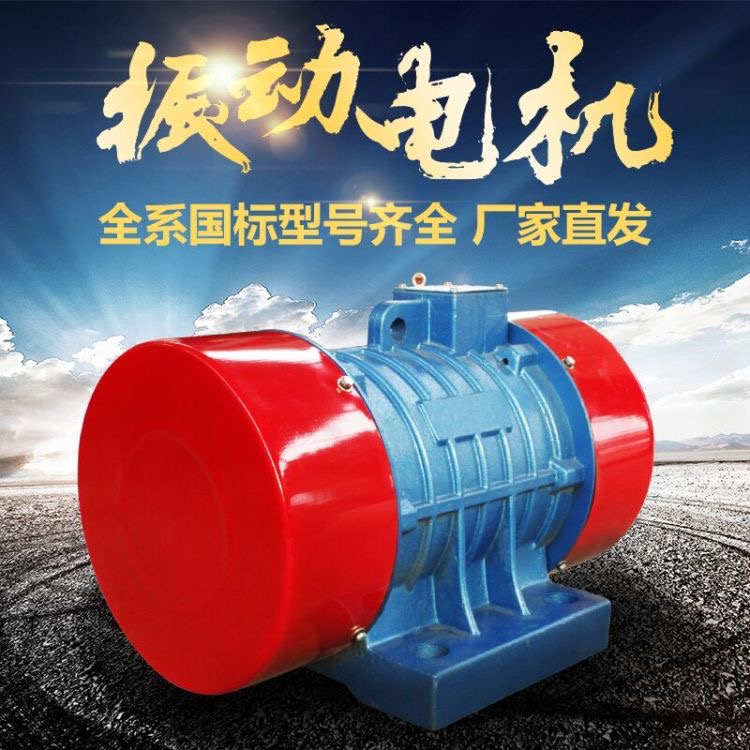

振动电机是由偏心机构与三相异步电动机组合而成,是动力和振动两源合一的特种振动源。

振动电机具有结构简单、安装方便、体积小、重量轻、运行可靠、通用性强、激振力可无极调整、可单台使用,也可多台组合成各种振动形式且维修量小等特点、在冶金、矿山、耐火、选煤、建材、化工、火电、粮食等行业应用极为广泛。

The vibrating motor is made up by eccentric mechanism and three phase asynchronous motor。It is special vibration source with power and vibration. The vibrating motor has some excellences: simple structure, easy fixing, small, light, steady working, commonality, nongraded exciting force adjustment, working alone or working together, and easy maintain. It is widely used in metallurgy, mine, fire-resistant, choice coal, tignum, chemical engineering, heat-engine, food supplies,and so on.

二、产品结构

二、产品结构

2, product structure

卧室振动电机主要由以下几部分组成

horizontal vibrating motor is mainly made up by:

1防护罩 2 偏心块 3轴承 4 支架 5 转子轴 6定位绕组 7机壳

1 shield 2 eccentric block 3 bearing 4 bracket 5 rotor spindle 6 orientation winding 7 shell

立式电机主要有以下部分组成

vertical vibrating motor is mainly made up by:

1 偏心块 2轴承 3 支架 4 转子轴 5定位绕组 6机壳

1 eccentric block 2bearing 3 bracket 4 rotor spindle 5 orientation winding 6 shell

三、使用条件与适用范围

3.use condition and sphere of application

1.振动电机适用环境温度为15~40。C。

1.the environmental temperature of application is between 15 degree and 40 degree.

2.海拔不超过1000米。

2. altitude is below 1000 metre.

3定子绕组的温升值(电阻法)不超过80C。

3. stator winding temperature is below 80 degree.( resistance measure)

4.轴承的允许温度(温度计法)不超过10589C。

4.bearing temperature is below 10580degree(thermograph measure).

振动电机适用于任何无防爆要求的场所,是各种振动设备的通用激振源。

vibrating motor applies to the place of no explosion prevention. It is currency vibration source, which can be used in all kinds of vibrant machine.

四、安装与调整

4. fixing and adjustment

1. 电机在吊装、搬运及安装时,切勿碰撞。

1. Do not collide.

2. 安装前应检查地脚螺栓孔与底座螺栓孔是否相符。

2. Before fixing ,check the applicability between tail bolt hole and the pedestal tail bolt.

3. 使用要求与标牌数据是否相符。

3. check the applicability between operating requirement and scutcheon data.

4. 停用三个月以上及新安装的电机,使用前应检查其绝缘电阻(380V,不小于0.38Mn,660V时,不小于0.66Mn)若已受潮,则须进行干燥处理,干燥温度不大于180C。

4.If the motor is halt for three months or the motor is new, before use it we should check the insulating resistance(380V, more than 0.38MΩ,660V, more than 0.66MΩ).If the motor is in damp ,we should be dry it ,the temperature is more than 180 degree.

5. 地脚螺栓采用防松装置,以防螺栓松动,使电机损坏。

Tail bolt must use locking device, to prevent the bolt becoming flexible and damaging the motor.

6. 若两台振动电机同时使用。

If two vibrating motors work together,

则a。两台电机反向旋转

a. two motors revolve opposite direction.

B.与筛体中心线对称。

b. symmetry for the center line of the sieve.

C.电机轴线与筛体中心线平行。

c. motor axis parallels the center of sieve.

7.安装完毕试运行2-4小时待一切正常后,方可投入使用。

7.After fixing , the motor can be used, which works 2-4 hours ,and business as usual

8使用中若激振力不能满足要求,可调整激振力的大小,以达到最佳使用效果

8.if the vibrant force is not settle for the demand, we should adjust the force.

9.振动电机激振力的调整。

9. adjustment for the vibrant force.

如果振动电机的激振力过大,产品出厂为最大激振力可将振动电机两端的防护罩拆下,同时调整电机两端的偏心块的相对角度(要求两端相位角始终保持一致),从而改变振动电机的激振力及在小范围内改变振幅的大小,调整后将防护罩装回。

If the vibrant force is oversize, we could remove the shields in either sides of the motor, and adjust the angle of the eccentric blocks in either sides of the motor for adjusting the vibrant force.(the phase angle must keep in step).After the adjusting, fix the shield.

五.维护与保养

5. maintenance

1. 定期清除外壳灰尘,以改善散热条件,但不得用水冲洗。

1. clean the dust in the shell regularly to improve the radiating conditions. But do not wash it in water.

2. 当海拔与环境温度均符合要求时,振动电机定子绕组的温度升限值(电阻法)为80C。轴承的允许温度(温度计法)不应超过105C

2. if the altitude and temperature accord with demand, stator winding temperature is below 80 degree( resistance measure),bearing temperature is below 105degree(thermograph measure).

3. 为延长轴承寿命,轴承应保持良好的润滑状态。

For dilating the bearing life, bearing should keep lubricative well.

A. 定期对轴承进行保养补充适量的润滑脂(润滑脂为二硫化钼复合钙基);2级电机注油量为轴承容腔的1/2,4、6级电机注油量轴承容腔的2/3。

a. supply right amount of grease lubricant(molybdenum disulphide grease);the oil mass for the two rank motor is half than bearing’s cubage, the oil mass for the four or six rank motor is two-part than bearing’s cubage.

B. 电机运行4-6月小修一次,运行一年大修一次,小修清除机体的积尘、污垢,检查电机绕组的绝缘电阻、接头、地线、连接部位的紧固螺栓是否松动,及时排除隐患。

大修时除进行必要的小修保养外,须查看轴承的磨损程度及线圈绝缘状况,必要时及时更换维修。

b. After the motor works for four-six months , it should be easy serviced. After one year, it should be heavy repaired. Easy servicing conclude cleaning dust over the shell, checking the insulating resistance in the motor winding, terminal, groundwire, the binding bolt in nterconnecting piece, to exclude hidden trouble in time.

Heavy repairing must check the degree of wear of bearing, and the insulated status of winding. Change the bearing and winding in time.

六.常见故障及处理方法

6. error and processing method

序号

Number 故障现象

Symptom 造成故障的可能原因

Cause for the error 处理方法

Processing metheod

一

一

电源接通后,振动电机不能转动

After plugging in, vibrating motor dose not work. 1、 定子绕组相间短路,接地以及定子绕组断路

2、 定子绕组接线错?BR>3、 负载过重或有卡阻现象

1. stator winding has been short, earthing or turnoff.

2. stator winding has been wired error.

3. overload or locking. a) 检查找出断路、短路接地部位,实行修复

b) 检查定子绕组接线,加以纠正

c) 减轻负荷或清除卡阻物

a) check the stator winding for short,earthing or turnoff.

b) Check stator winding’s wiring.

c) Light load or clean the locking.

二 电机运行时转速低于额定值

When the motor is working, rotate speed is below rating speed. 电机转子断裂

The rotor of motor is ruptured. 更换铸铝转子

Change the cast aluminium rotor

三 支架腿断裂

The leg of bracket is r支架腿断裂The leg of bracket is ruptured 1、 地脚螺栓没有旋紧

2、 与地脚平面配合

1. stone bolt is flexible

2. the planes of fitting badly 1、 旋紧螺栓

2、 重新加工两平面,达到吻合良好

1. wind the bolt.

2. process the two planes again, for fitting well.

四 电机温升过高或冒烟

The high temperature of motor or smoking. 1、 负载过重

2、 定转子绕组断路

3、 定子绕组接线错误

4、 定子绕组接地或相间短路

5、 电机转子断裂

6、 定转子相擦

1. overload

2. stator winding is turned off.

3. stator winding is wired error.

4. stator winding is earthed or short.

5. The rotor of motor is ruptured.

6.The stator rubs against the rotor.

1、 减轻负载

2、 查出断路位,加以修复

3、 检查定子绕组接线,加以纠正

4、 查出接地和短路部位加以修复

5、 更换铸铝转子

6、 检查电动机气隙、配重以及轴承磨损等情况

1. light load

2. check the turnoff.

3. check the stator winding’s wiring.

4. check the earthing and short.

5. Change the cast aluminium rotor

6. inspect the air gap of the motor,inspect the configured weight of the motor,inspect the abrasion of bearing in the motor,etc.

五 电机外壳带电 宏达梅广州 130726338986 0373-2632855

Motor shell is electriferous 1、 接地不良或接地电阻太大

2、 绕组绝缘损坏

3、 绕组受潮

4、 接地板损坏或面内的油垢太多

1. earthing badly or earthing resistance more large.

2. winding insulation is broken.

3. winding is damp.

4. earth-plate or inside of plate has much oil dirt. 1、 找出原因,并采用相应措施

2、 修补绝缘,并以浸漆处理

3、 干燥处理或浸漆干燥处理

4、 更换或清除接地板

1. Find the cause, and adopt a measure

2. mend the insulation, and dip lacquer

3. drying process or dipping lacquer process.

4. change or clean the earth-plate

六 轴承过热

bearing running hot 1、 轴承磨损过度或质量有问题

2、 轴承油脂过多或过少,型号选用不当或质量不好

3、 轴承内圈与轴配合过松或过紧

4、 轴承外圈端盖的配合过松或过紧

5、 端盖与轴承盖的两侧面与轴承的两侧面装配不平行

1. bearing excessive wearing or bearing quality issues

2. grease lubricant is overmuch or shortage

3. bearing inner race coordinate with the axis much loose or tight

4. bearing outer ring coordinate with the closure much loose or tight

5. the closure two sides do not run parallel with the bearing two sides. 1、 更换轴承

2、 调整或更换轴承脂

3、 过松时可在轴上喷涂一层金属,过紧时可重新加工轴

4、 过松时可将端盖的轴承孔扩大后镶套,过紧时可重新加工轴承孔

5、 将两侧端盖或轴承盖装平,再旋紧螺栓

1. change bearing

2. change or adjust the grease lubricant

3. if it is loose, paint layer metal. If it is tight, process the axis again.

4. if it is loose, expand the bearing hole of the closure . If it is tight, process the bearing hole of the closure again.

5. fix the two sides closure or bearing cap even, wind up the bolt.

宏达振动梅广州 15893821877 0373-2632855

七、储存与运输

7. storage and transport

1.振动电机不得存放在露天或潮湿的地点。

1. vibrating motor can’t store the open air place or damp place.

2.在运输和储存过程中不准倒置与碰撞。

2.the storing and transporting process must not convert or collide the motor.

3.避免与酸碱等腐蚀物质接触。

3. prevent from corrosive like acid base matter.